Aerospace

Aerospace Components Manufacturers

MW Components has 20+ aerospace component manufacturers across the country producing made-in-the-USA components for a variety of uses. We offer custom aerospace springs, fasteners, precision components, and more.

Aerospace Part Manufacturing

The aerospace industry demands products that meet exact specifications and the highest standards for reliability and quality. MW Components meets and exceeds those demands. Through a combination of technology and in-house engineering and manufacturing expertise, we are able to design, manufacture, and deliver the highest quality products and sub-assemblies in the industry.

Our unique processes and equipment ensure quality, control, and performance for the most demanding jobs, including lightweight, high-temperature, low-temperature, and high-corrosion applications.

Our locations stock material to support the rapid turnaround required in aerospace. We stock Stainless Grade 17-7 PH®, which is ideal for aerospace applications and can deliver 17-7 compression springs just two weeks after receiving a purchase order. View the 17-7 brochure to learn more or contact us to place an order.

Processes and Parts that Meet Rigorous Aerospace Standards

MW’s aerospace products are commonly specified in mission-critical components, so everything we do meets the rigorous system safety and performance standards of organizations such as the FAA, DoD, and NASA. Our customers know our aerospace components will continue performing as specified year after year – even in the most extreme operating conditions imaginable.

Aerospace at a Glance

YEARS SERVING INDUSTRY

50+

COMPLIANCE

ISO 9001

AS9100D

FAA Compliant

DoD Compliant

NASA Compliant

ITAR Compliant

Boeing DPD approved for CATIA files

Member of NBAA

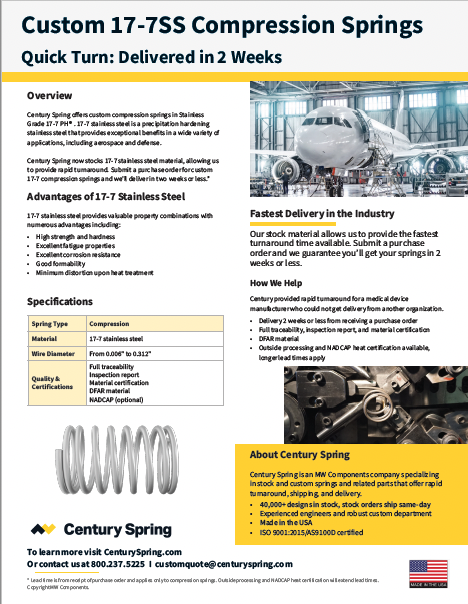

2-Week Delivery on Custom 17-7SS Compression Springs

Need aerospace springs fast? Our Century Spring location offer 2-week delivery on custom 17-7 stainless steel compression springs. View the brochure to learn more or request a quote.

Stock, Standard and Custom Aerospace Components

We design and manufacture springs, fasteners, wire forms, microlens arrays, fiber optics, and related precision metal or plastic components for a wide range of aerospace applications. We are dedicated to the on-time delivery of quality, cost-effective parts. Our processes and CNC equipment ensure consistency, reliability, and fast delivery for a large selection of aerospace components. Whether you’re looking for components for engines and propulsion, flight control, interiors, landing gear, or space exploration vehicles, we have the parts you need.

Aerospace Springs

MW had decades of experience producing the highest quality metal components, with custom aerospace springs as one of our specialties. Many of our facilities are ISO9001 and AS9100D certified and FAA compliant. We produce aerospace springs only from top of the line material via processes that ensure performance and reliability for critical parts. You'll find our springs in everything from engine control and bakes to propulsion systems.

In addition to stock and standard components, we design custom solutions for the most precise applications imaginable. Our technical expertise and commitment to pushing the boundaries of engineering excellence makes us one of the most innovative aviation suppliers in the market today. Our expert team specializes in manufacturing NAS hardware including spacers, standoffs, as well as springs and various other metal and plastic components. We're experts in working with wire diameters between 0.010” to 1.000”, including shaped wire. We also offer flat springs and stampings from 0.010” to 0.250” in thickness.

Why Choose MW?

Parts used in aerospace projects often require quick turnaround at the highest quality. MW Components has an unparalleled reputation for quality and we go to great lengths to support your timeline. We have also have everything suppliers need for product development and manufacturing all in one place, so you’ll reduce the number of vendors necessary for the project and deliver it on schedule.

Specialized Aerospace Manufacturing Services

Our customers rely on us for quick quote turnaround, rapid prototyping, rigorous testing, and unique expertise in custom-focused aerospace manufacturing solutions. The depth of experience of our technical team helps us deliver rapid response times for both large run orders and difficult designs.

The Highest Quality Materials

Our team has extensive expertise in working with specialty materials sourced from over 20 locations in the USA. We also have a full network of NADCAP registered suppliers for controlled processes such as heat treating, magnetic particle inspection, liquid penetrant inspection, shot peening, plating, and specialty coatings.